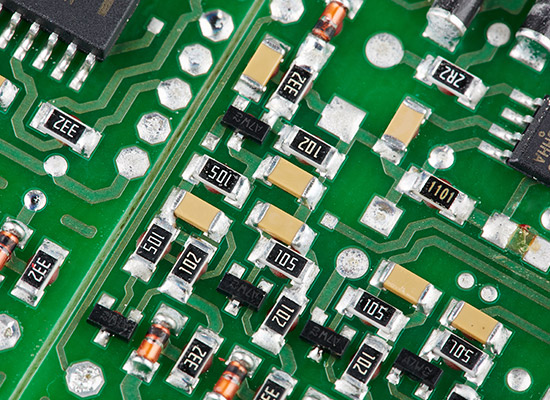

FICG (also known as PRIME Technology) has accumulated more than 17 years of experience in the optical module industry and is among the early adopters of optical transceiver SMT manufacturing within the optical communications sector. As data rates continue to scale rapidly, we combine high-precision manufacturing with advanced packaging technologies to support customers from product qualification through stable mass production.

In terms of process and packaging technologies, we offer advanced capabilities including CPO, COB, Silicon Photonics (SiPh), and Flip-Chip packaging, together with high-speed signal integrity and reliability engineering. These capabilities ensure signal integrity, thermal performance, and long-term reliability under high bandwidth and high power-density operating conditions.

We also provide customized process integration services for next-generation optical modules. By tailoring SMT, packaging, and testing strategies for different architectures—such as LPO, LRO, TRO, NPO, and CPO—we help customers accelerate new module development while ensuring a smooth transition to volume production.

In 2026, FICG (PRIME Technology) participates in APE (Asia Photonics Expo) in Singapore, presenting a comprehensive portfolio of high-speed optical transceiver manufacturing solutions. The showcased solutions covered high-precision PCBA, advanced packaging, and multi-generation mass-production support, enabling customers to address the growing demands of high-speed data transmission and AI-driven applications.

Advanced Packaging for Optical Transceivers

As optical modules advance toward the 800G to 1.6T generation, we continue to drive the development of high-speed optical module products and system architectures. We have successfully completed the introduction of 800G OSFP and QSFP-DD optical transceivers, supporting DR4 and SR8 architectures and adopting Flip-Chip processes to meet increasing signal density and power requirements.

Moving further into the 1.6T generation, FICG focuses on highly integrated module architectures, including 1.6T OSFP, SPTR, Flip-Chip PIC/PD integration, and low-power LPO/LRO architectures, addressing the core requirements of AI and data center applications for ultra-high-speed interconnects, energy efficiency, and system scalability.

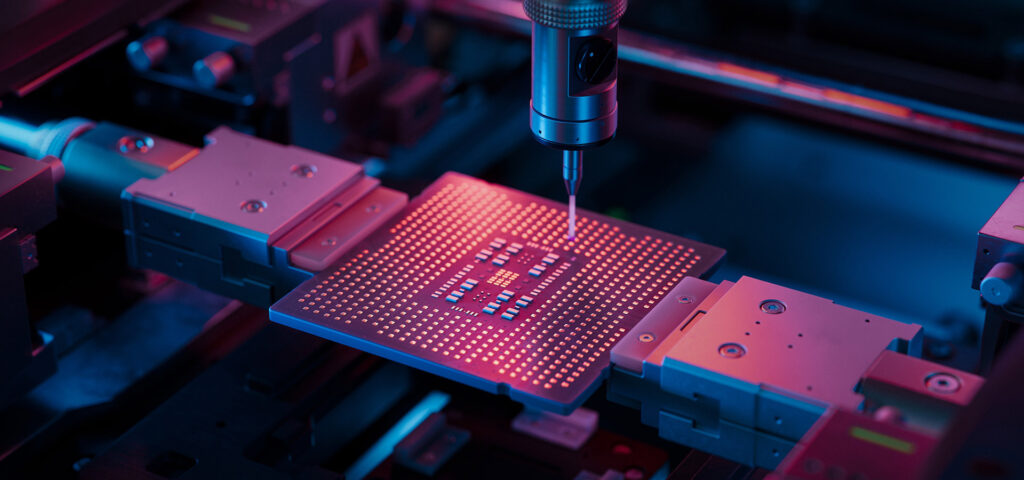

SMT × Semiconductor Process Integration

With next-generation optical transceivers demanding higher levels of integration, FICG has established an integrated manufacturing platform that bridges SMT and semiconductor processes, effectively connecting PCBA manufacturing with advanced packaging technologies. This platform encompasses bare-die handling, Flip-Chip assembly, fine-pitch bumping, die bonding, and PIC/PD integration, enabling a seamless manufacturing flow from die level to module level.

By integrating SMT technology with semiconductor process expertise, FICG transforms complex module architectures into repeatable and scalable manufacturing solutions. Through long-term mass-production collaboration, we help customers accelerate new product introduction while maintaining quality consistency and sustainable high-volume production.

Visitor Information

Exhibition: 2026 Asia Photonics Expo (APE)

Date: February 4–6, 2026

Venue: Sands Expo and Convention Centre, Level 1, Singapore

(10 Bayfront Ave, Singapore 018956)

Booth No.: A521

Visitor Registration:

https://reg.asiaphotonicsexpo.com/en/index.html?ly=EN-Web2026-VisitorInfo

Visit us at Booth A521 during APE, or fill out the contact us form (Click Here) to arrange a discussion in advance.